Solar Panels Inspection Using Drones

Ongoing maintenance and malfunction detection.

15 May 2020

5 min read

Summary

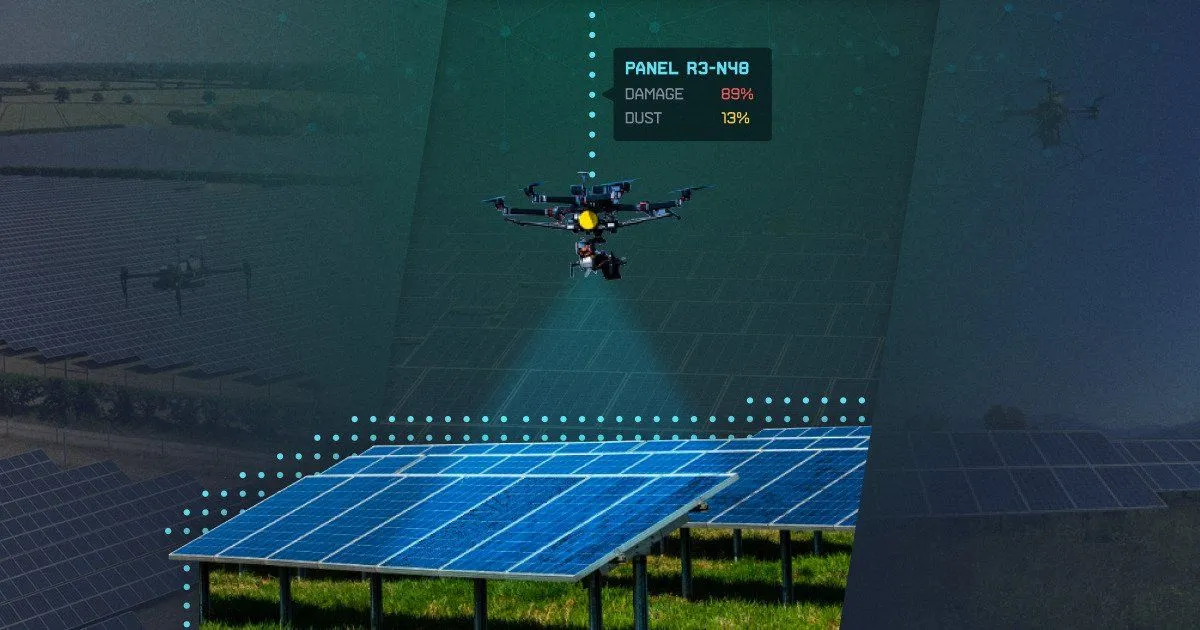

- With the solar industry growing exponentially, the need for solar panels ongoing maintenance and malfunction detection surges proportionally. As solar panels break frequently, plant and facility managers are seeking efficient, safe, and inexpensive ways to detect solar panel faults. Drones like no other technology offer an efficient solution for panel inspection.

- While many market players offer solar panels inspection, only a handful process video from drones and provide reports on breakdowns, coordinates, energy and money losses. Our client's goal is to build the first full-cycle solar panel inspection service.

- Together with our client, we have built the first full-cycle solution powered by Computer Vision technologies enabling timely defect detection and functioning analytics for solar panels providers and customers.

Tech Stack

GStreamer

OpenCV

Python

TensorFlow

TensorRT

Next Case

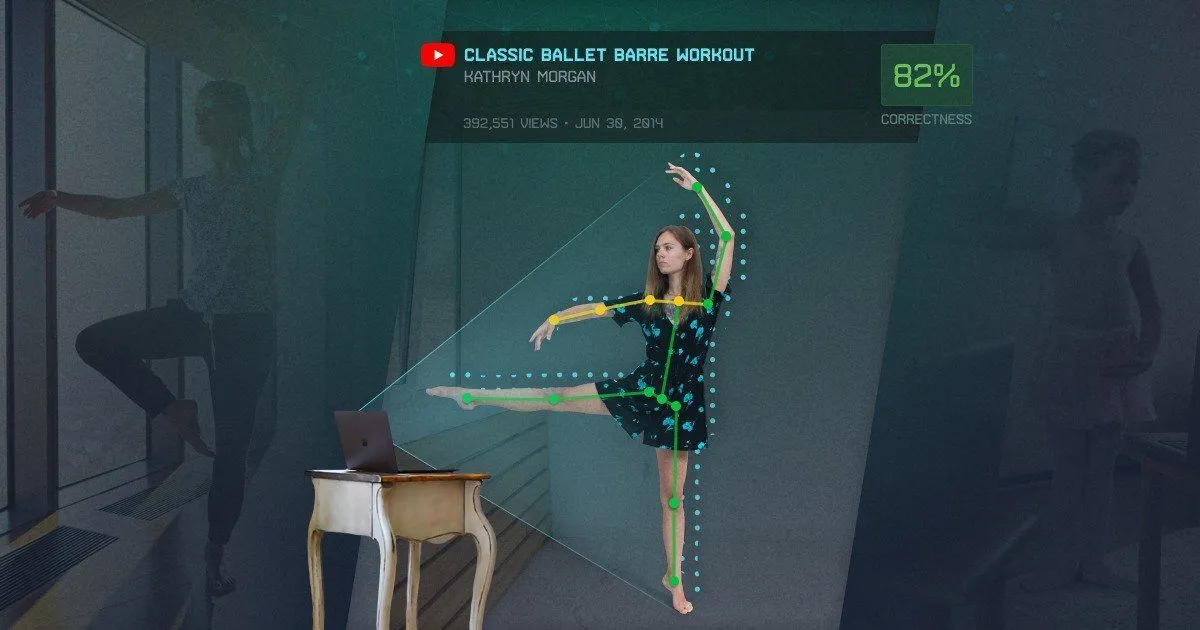

CV-Powered Personal Coach Platform for Amateur Athletes

AI-Powered approach in dance education.

Timeline

1 week

Data Labelling and Processing

Data Engineer

1 week

Solution Architecture Design

Solution Architect

2 weeks

Hypothesis Generation & Validation

Deep Learning Researcher

1 week

Architecture Modelling

Deep Learning Researcher

3 weeks

Training & Tuning Cycle pt.1

Deep Learning Researcher

4 weeks

Training & Tuning Cycle pt.2

Deep Learning Researcher

3 weeks

Video Streaming Backend Development

Backend Developer

Data Engineer

3 weeks

Web Platform Development

Backend Developer

Frontend Developer

1 week

Integration & Deployment

Dev Ops

Tech Challenge

- Real-time binary segmentation of solar panels from the video.

- Choosing the "moment" of the panel classification at the right angle.

- Mapping the corresponding panel to its position on the map.

- Creation of interactive report with different view parameters.

- Creation of corresponding .kmz file with coordinates mapping.

- Creation of energy and money loss analytics based on classification results.

Solution

- Segmentation and tracking of panels based on TRGB video data.

- Optimization of processing with TensorRT.

- Using U-net for binary segmentation.

Impact

- data root labs have built a web service that allows performing one-time and routine drone inspections.

- The service also makes it possible to download and upload external video for analysis.

- Based on the video from the drones, users receive a detailed interactive report in .kmz format as well as an analytical summary highlighting potential defects, energy and money losses.

Have an idea? Let's discuss!

Book a meeting

Yuliya Sychikova

COO @ DataRoot Labs

Do you have questions related to your AI-Powered project?

Talk to Yuliya. She will make sure that all is covered. Don't waste time on googling - get all answers from relevant expert in under one hour.

Talk to Yuliya. She will make sure that all is covered. Don't waste time on googling - get all answers from relevant expert in under one hour.

OR

Important copyright notice © DataRoot Labs and datarootlabs.com, 2026. Unauthorized use and/or duplication of this material without express and written permission from this site’s author and/or owner is strictly prohibited. Excerpts and links may be used, provided that full and clear credit is given to DataRoot Labs and datarootlabs.com with appropriate and specific direction to the original content.