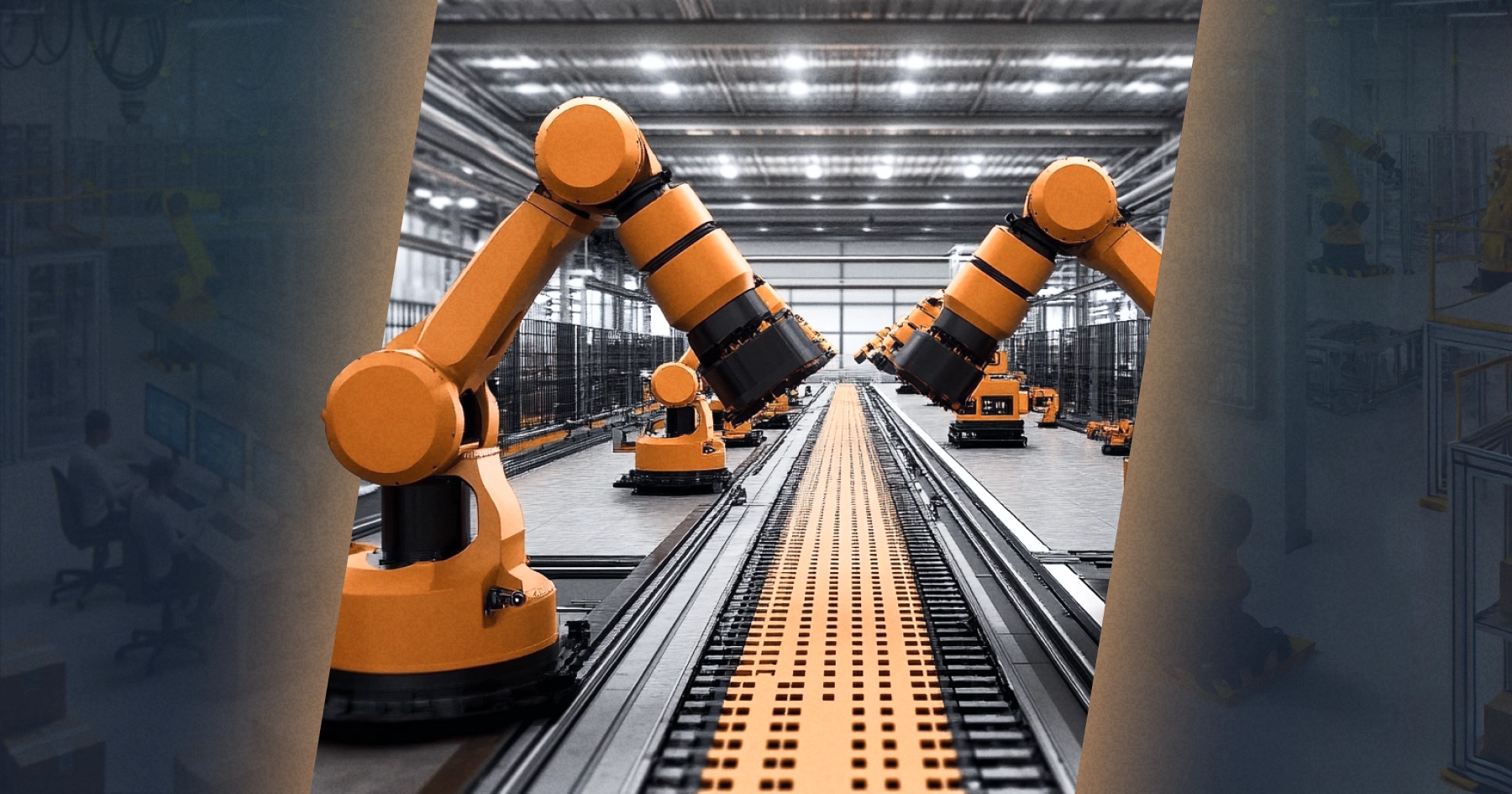

Warehouses Are Getting Smarter: Inside Eiratech Robotics with Founder Alex Tabolkin

How Eiratech Is Driving Innovation in Warehouse Robotics From Vision to Deployment

Alex Tabolkin is the CEO and Founder of Eiratech Robotics, a Dublin-based company that develops a robotics automation platform designed to simplify warehouse operations. The company's platform automates logistics picking operations through the use of a fleet of proprietary robots for e-fulfillment, materials handling, kitting, and retail purposes, enabling businesses to increase the efficiency of factories and warehouses.

There are many definitions of autonomy. How do you define autonomous in your solution?

We define autonomy as the ability to operate without human input once deployed. Our robots use different navigation methods depending on the application, and they can reroute in real time if their path is blocked or if the layout changes, which happens more often than you’d think.

They also report environmental issues such as tag positioning, angle deviations in turns, low-traction zones, or congestion. This data is fed back to the RMS, which updates the shared map using layered “road signs” to guide the rest of the fleet.

Another critical dimension of autonomy is recoverability: how many issues can the RMS resolve automatically, and how easy is it for an unskilled operator to fix what it can’t? In our view, these are the real benchmarks that separate a truly advanced robotic system from a basic one.

Eiratech focuses heavily on Goods-to-Person (G2P) systems and mobile robotics. Where do you see the greatest unmet opportunities in warehouse automation today, especially for autonomous ground vehicles (AGVs)?

One of the biggest unmet opportunities in warehouse automation is in the next generation of tote movers: compact, flexible AGVs designed for high-frequency, short-range material handling. These often get overlooked compared to larger systems, but they’re critical for fast-moving environments where seconds and centimetres matter.

We’re also seeing a clear shift in the way robot models are evolving. Instead of universal platforms that try to do everything, the trend is moving toward task-specific robots when machines optimized for particular workflows, payloads, or environments. That specialisation drives both performance and ROI, especially when those robots can integrate smoothly into broader systems.

What I admire about the US approach is the opposite: a willingness to try, fail, learn, and adjust. That mindset dramatically shortens the adoption curve and creates a much more fertile environment for robotics and emerging tech.

The AGV space has become increasingly competitive, with big players scaling fast. What differentiates Eiratech’s approach, both technologically and commercially, from others on the market?

What sets Eiratech apart is our focus on high-performance AGVs that remain flexible and simple to operate. Technically, we’ve built systems that support higher travel speeds and tighter navigation tolerances than most competitors on the market, which means fewer robots can do more work. In real-world deployments, we’ve achieved up to a 50% reduction in fleet size compared to typical G2P setups.

A good example of our design thinking is how we handle safety when visibility is blocked. When a robot is carrying a tote or rack, its onboard sensors can’t always detect what’s directly ahead, like a human hand in its path. Instead of relying solely on bumpers or emergency stop buttons, we’ve installed IoT sensors. These detect human presence early and trigger the robot to slow down or stop if needed. Crucially, the rest of the system keeps running and only the local robot adjusts. That smart, decentralised response can save up to 5% of working time compared to systems that trigger full emergency stops.

Usability is another key differentiator. Our entire system is controlled through a live map interface, where users can assign tasks, manage totes, goods, racking, pods, track robot status and charging levels, monitor warehouse crew load and activity, and manage zones and inventory in real time, without needing a team of engineers to operate it.

From your perspective, how are customer expectations evolving regarding robotics in logistics?

Customers used to look at robotics as a one-off efficiency upgrade, a way to cut labor costs or reduce errors. Now, expectations have moved beyond that. They’re not just buying robots; they’re looking for systems that can scale with their operations, adapt quickly to change, and integrate cleanly with the rest of their tech stack.

Another shift we’ve seen is internal. Customers themselves are not static. Management and operations teams change every few years, and often the new people coming in don’t fully understand why the robots were installed in the first place, which creates a new kind of expectation. They want to see clear KPIs, up-to-date performance data, and a defined roadmap for the system’s future. In other words, they expect robot lifetime management, not just a one-time deployment.

A robot sitting in the corner working isn’t enough anymore. They want data. They want to know: where’s the bottleneck, what’s underperforming, how fast can I reconfigure this setup when demand shifts?

That’s why smart integrators rarely push a single vendor. They build portfolios, using different robots and software layers to deliver the right solution, not just the standard one.

At the same time, there’s a growing expectation that the system will improve over time. Our RMS, for example, learns from ongoing use by identifying congestion patterns, route inefficiencies, or resource imbalances. That kind of continuous optimisation is what turns automation into a living part of the operation, not a static asset.

So yes, customers still care about ROI, but they’re also asking, “Will this system keep evolving with us?” That’s the shift we’re seeing.

Our system uses computer vision and learning models to monitor plant growth and health. It continuously analyses crop clusters and signals to the RMS when a group is ready to be moved to another zone or chamber.

You've successfully deployed Eiratech systems across different geographies. Are there particular market challenges or adoption patterns you notice between, say, Europe vs. the US, vs. Asia?

We don’t currently have a presence in Asia. Markets like China are dominated by strong local players, with heavy government backing and a different operational philosophy when it comes to efficiency and workforce safety. That makes it tough for non-domestic vendors to break in, especially without scale.

That said, both China and the US are pushing the boundaries when it comes to adopting new tech. They move quickly, piloting, iterating, and scaling without getting stuck in endless feasibility loops. Honestly, most of the rest of the world is trying to catch up.

Europe, by contrast, tends to be more risk-averse. There’s still a cultural hesitation around B2B startups, not just from enterprise customers, but sometimes even within the integrator ecosystem itself. It’s that old mindset: “Nobody ever got fired for not innovating.”

A typical example: many large European companies launch internal innovation units, only to restructure or quietly shut them down every two to three years. That constant churn kills momentum before anything meaningful can scale. And when you factor in the average 12-month sales cycle for enterprise-level tech, it becomes almost impossible for real innovation to take hold as the clock runs out before the pilot even finishes.

What I admire about the US approach is the opposite: a willingness to try, fail, learn, and adjust. That mindset dramatically shortens the adoption curve and creates a much more fertile environment for robotics and emerging tech.

AGVs are often spoken about in the context of warehouses, but where do you see potential for Eiratech's technology beyond traditional warehousing environments?

There’s significant potential for AGVs beyond traditional warehousing, and we’re already seeing that with some of our deployments. For example, we’ve worked in production environments where robots handle just-in-time material delivery, and in online grocery fulfilment operations where speed, accuracy, and uptime are critical.

We see strong opportunities in retail back-of-house automation, manufacturing support logistics, farming, hospitality, and healthcare, where efficient movement of goods or supplies can reduce human load and errors.

In general, anywhere that requires fast, repeatable, and reliable transport of goods in dynamic or constrained environments, our technology brings real operational value. As more industries digitise their physical operations, the demand for this kind of flexible automation is only going to grow.

What’s missing today is a software layer that can analyse a warehouse operation, understand customer needs and constraints, and recommend the most efficient solution across vendors, robot types, or automation segments. Not just pushing a product, but designing the right answer.

Looking ahead, how do you see the relationship between AGVs and emerging technologies like AI, Computer Vision, and IoT evolving over the next 5 years?

These technologies aren’t fully integrated yet, but they’re clearly heading in that direction. In the AGV world, we already see how AI, computer vision, and IoT are starting to converge, each playing a distinct role in creating smarter, more responsive systems.

At Eiratech, we use machine learning daily, mostly for environmental perception. That includes things like obstacle recognition, localisation, and interpreting sensor input in real time. It helps our robots operate more reliably in dynamic environments. But for core tasks like fleet coordination or scheduling, we still rely on deterministic logic because predictability, uptime, and safety are critical in industrial settings.

That said, we’re seeing different roles for AI in other verticals. For example, we’ve developed a robot for vertical farming, where AI plays the lead role. Our system uses computer vision and learning models to monitor plant growth and health. It continuously analyses crop clusters and signals to the RMS when a group is ready to be moved to another zone or chamber. The robot then executes the move without the operators’ involvement. That’s a real case where AI is directing the process, not just supporting it.

IoT is the connective tissue across all of this, enabling real-time data exchange between robots, infrastructure, and enterprise systems. Whether it’s temperature sensors, safety zones, or shared location data, connected infrastructure turns static automation into something more adaptive.

So in the next five years, I don’t think we’ll see one big breakthrough in warehouse robotics. What we’ll see instead is a gradual but meaningful shift where AI, computer vision, and IoT are no longer treated as add-ons, but are properly integrated into systems designed for real-world use.

AI will handle perception where it makes sense, rule-based logic will continue to drive core operations, and IoT will connect the dots between robots, infrastructure, and backend systems. The progress won’t be flashy, but it’ll be foundational, and the platforms that get this balance right will define the next wave of industrial automation.

You’ve been vocal about the gap between ‘hype’ and ‘reality’ in robotics. What misconceptions about AGVs or warehouse robotics do you think the industry still needs to correct?

One of the biggest misconceptions is that companies are buying robots. They’re not. They’re buying a way to keep up with demand, labour shortages, and unpredictable growth. Robotics just happens to be the right tool when manual processes start slowing them down.

At the same time, many customers are unsure what to invest in. They’re weighing different options, not just between vendors but between entirely different approaches. Should they go for robots, traditional automation, or do nothing and wait? Should they invest in picking, moving, or storage systems? And if they choose robots, which type fits their environment best?

This uncertainty creates a huge opportunity for the market. What’s missing today is a software layer that can analyse a warehouse operation, understand customer needs and constraints, and recommend the most efficient solution across vendors, robot types, or automation segments. Not just pushing a product, but designing the right answer.

Helping customers make those decisions with data, not guesswork, is where the next real value will come from.

If you’re building a robotics company, go where your B2B customers are hungry for change and your capital can go further.

Building hardware-intensive companies in Europe isn't easy. What lessons have you learned from scaling Eiratech that you’d share with other robotics founders?

One of the hard lessons we’ve learned is this: if you can avoid starting in Europe, do. It’s a tough place to build and scale a hardware company, especially in robotics. The market tends to prioritise protecting what already works instead of pushing for new levels of efficiency. That mindset slows everything down, from adoption to funding to partnerships.

The other major challenge is capital. Even raising enough for day-to-day operations is difficult. Hardware is a capital-intensive sector, and the cashflow pressure is constant. But in Europe, you’re often working with 30 to 60 day payment terms, which means small startups are effectively crediting big enterprises and absorbing all the risk. When your customers are slower than your burn rate, cash stops being strategy and starts being survival.

If you’re building a robotics company, go where your B2B customers are hungry for change and your capital can go further. In those markets, your technology is seen as a strategic advantage, not a risk, and you’re more likely to find partners, buyers, and investors who understand the pace and pressure of building physical products.

In the most repetitive, high-throughput environments [...], I think we’ll see a clear trend toward phasing people out of certain tasks by 2030.

If you had to make a bold prediction, how would the role of human workers in automated warehouses look by 2030 — more collaboration with robots, or less human involvement altogether?

In the most repetitive, high-throughput environments, especially in e-commerce and large-scale logistics, I think we’ll see a clear trend toward phasing people out of certain tasks by 2030. The push for speed, consistency, and predictability makes full automation an attractive path in those settings. But even then, it’s not about replacing people entirely; it’s about reallocating human effort to where it adds the most value.

That said, most warehouses around the world are small and often operate with minimal infrastructure and highly manual workflows. For these businesses, full automation doesn’t yet make economic or operational sense. There’s still no plug-and-play robot that can handle mixed workflows, low-volume SKUs, or personalised tasks in a scalable way.

I’ve seen this firsthand. One customer boosted their sales simply by installing a basic box-gluing machine. That one change let them increase their minimum pack size from six to twelve bottles, making fulfilment more efficient and consistent. For them, that was their version of automation - simple, effective, and directly tied to growth.

Another example: a small coffee roaster installed a five-metre packing conveyor after their roasting line. That alone dramatically improved throughput and reduced handling time. No robotics involved, just a smart investment at the right time.

So while the largest, most structured operations may tend toward full automation, the majority of the industry will still rely on people, not because they’re behind, but because that’s what their business model demands. The real opportunity lies in building automation that fits the scale, maturity, and complexity of each operation.