AI Robotics and Simulation for Enhanced Quality Control

Quality verification through inspection and analysis of components during manufacturing.

Summary

-

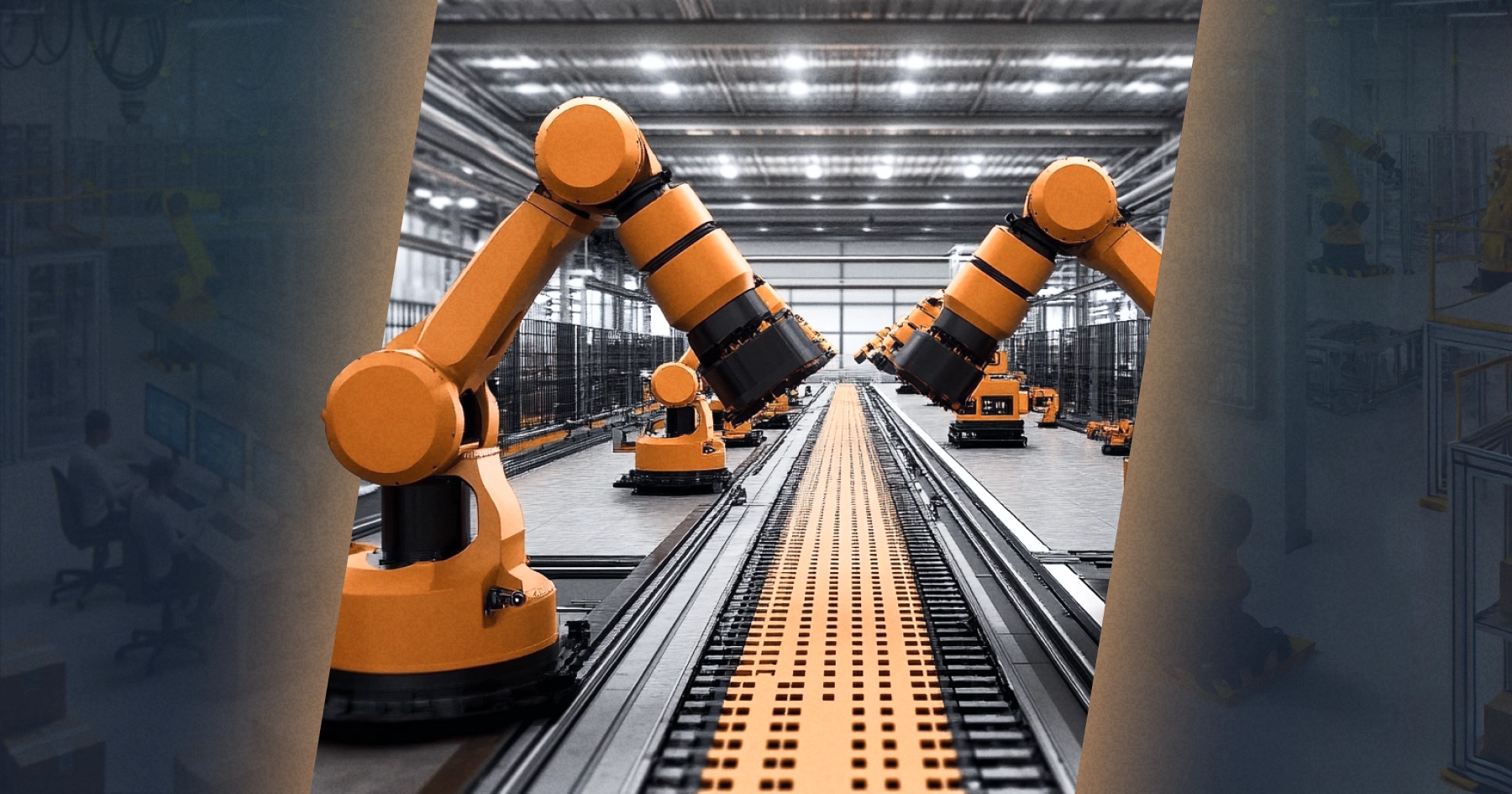

An inventive client startup is revolutionizing the use of AI robotics in manufacturing. The company focuses on high-mix production, which involves making different types of products with various specifications.

-

They intended to develop a simulation to identify product’s deformations using sensors to scan details and compare them with perfect parts. Therefore, we employed this solution to deal with some high-mix manufacturing problems and to increase accuracy and productivity in processes.

-

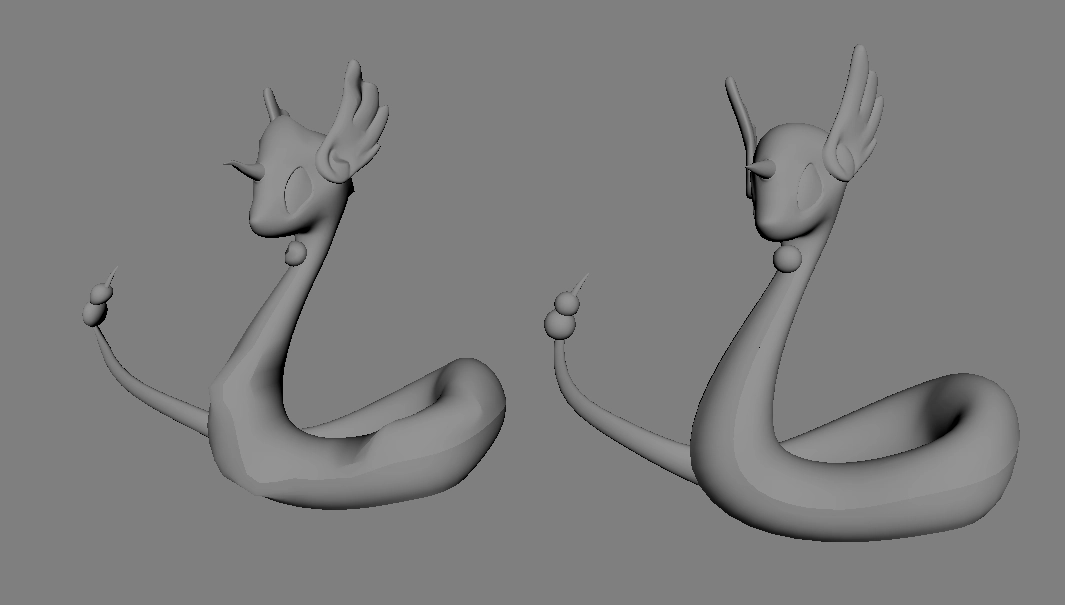

The team used the NVIDIA Omniverse Isaac Sim platform to make an advanced simulation, with the integrated client’s robot prototype created in Onshape. A critical component was point cloud comparison using CloudCompare software for accurate and fast identification of discrepancies in manufactured parts.

Tech Challenge

-

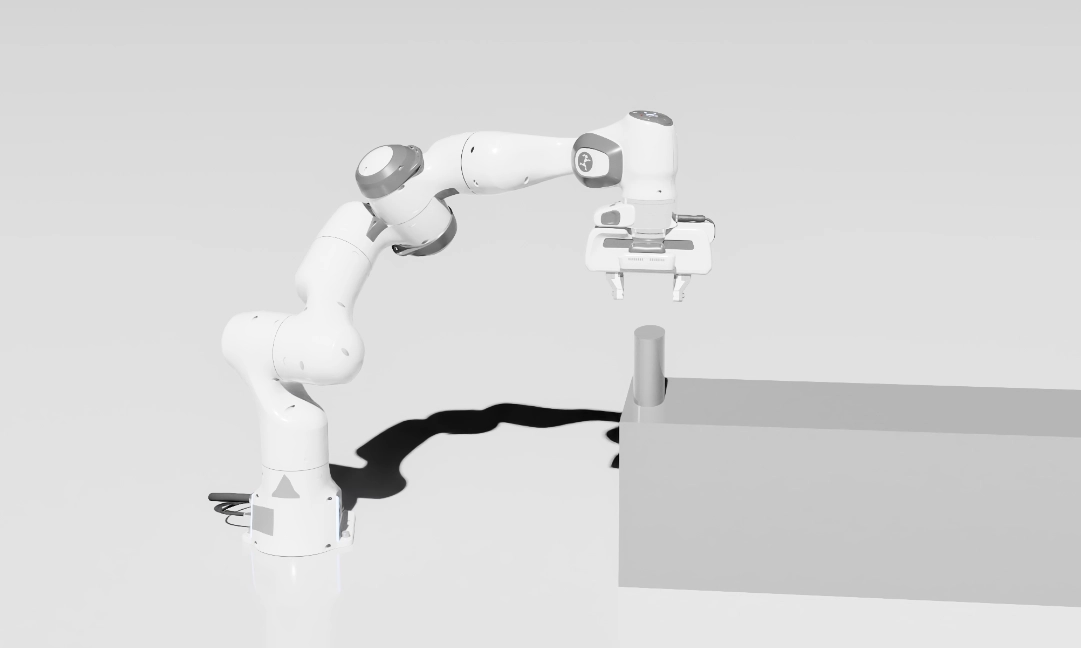

The first issue for DataRoot Labs was to bring the client’s robot prototype into Isaac Sim and keep its differentials, such as dynamic joints and physical properties. Apart from this, it was essential to set up a hyper-realistic scene and code the flow of imitation with great care. This setup should ensure that each robot goes through every step by specified instructions.

-

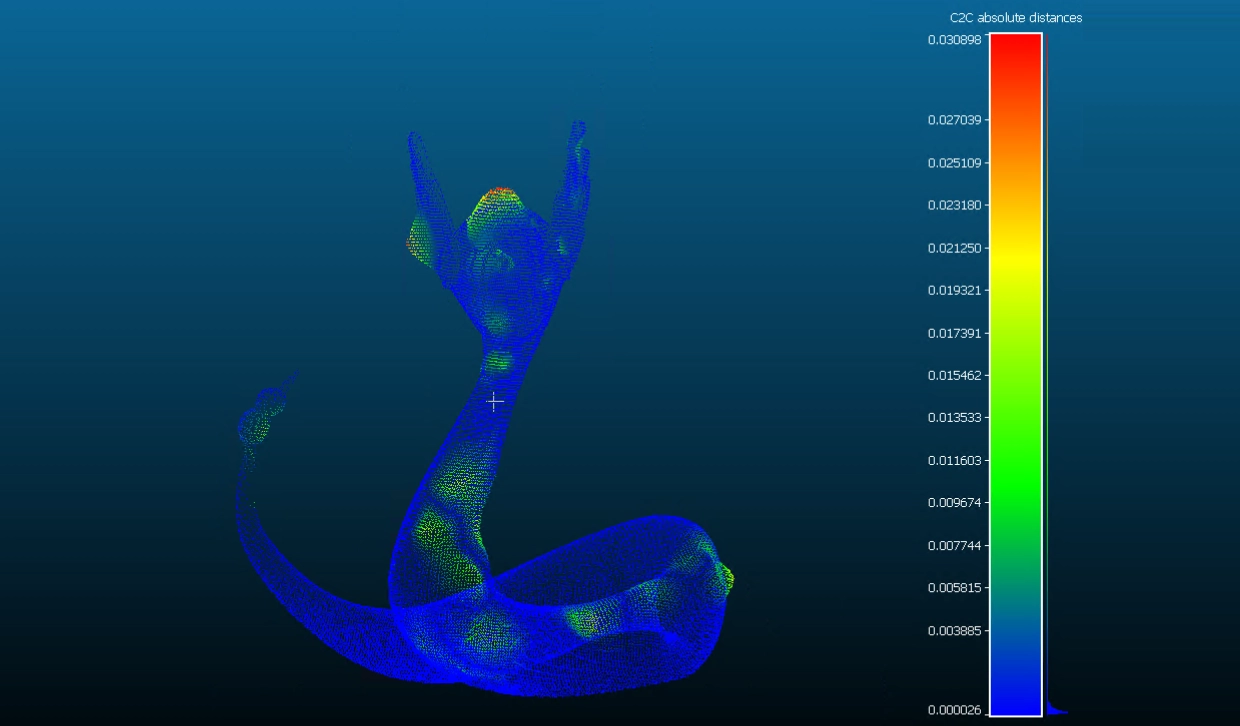

Efficient part point cloud comparison involved isolating Inspected components from other objects in the point cloud, especially the vise that holds them while rotating. Additionally, all noises from the sensor that originated from the LiDAR device have to be cleared away. The resultant scan comparisons should be vivid enough so that any deformity could be detected at a glance.

Tech Stack

Delivery Timeline

Imagine a manufacturer producing custom automotive parts for various car models. Each model requires different types of components with unique features. Once, a critical batch of engine components, designed differently, needs to be inspected. Processing each element takes an extensive amount of time and effort.

Solution

- We started by bringing the robot prototype into the NVIDIA Omniverse Isaac Sim. This highly sophisticated simulation allowed us to design and test robotic interactions within secured dynamic environments, ensuring system accuracy before physical implementation. Every joint was inspected to keep the robot’s dynamic and physical attributes intact. The joints must have the right tree-like structure for accurate robotic movements.

- One factory-made part is picked up by one robot and put into a vise held by another robot. After that, the vise closes around the detail and rotates, while the LiDAR sensor scans it. The rotation aims to capture all dimensions and features on the part with a 3D point cloud.

- We process the point cloud data using CloudCompy, a tool based on CloudCompare to separate the vise from all other parts of the point cloud so that only the part itself remains focused upon without its surrounding.

- Finally, we compare the processed point cloud against a perfect, predefined model. This way, if any misshapes or defects occurred during manufacturing, it’s easy to identify them. All detected deviations can be corrected unmistakably, which reduces waste and boosts production efficiency.

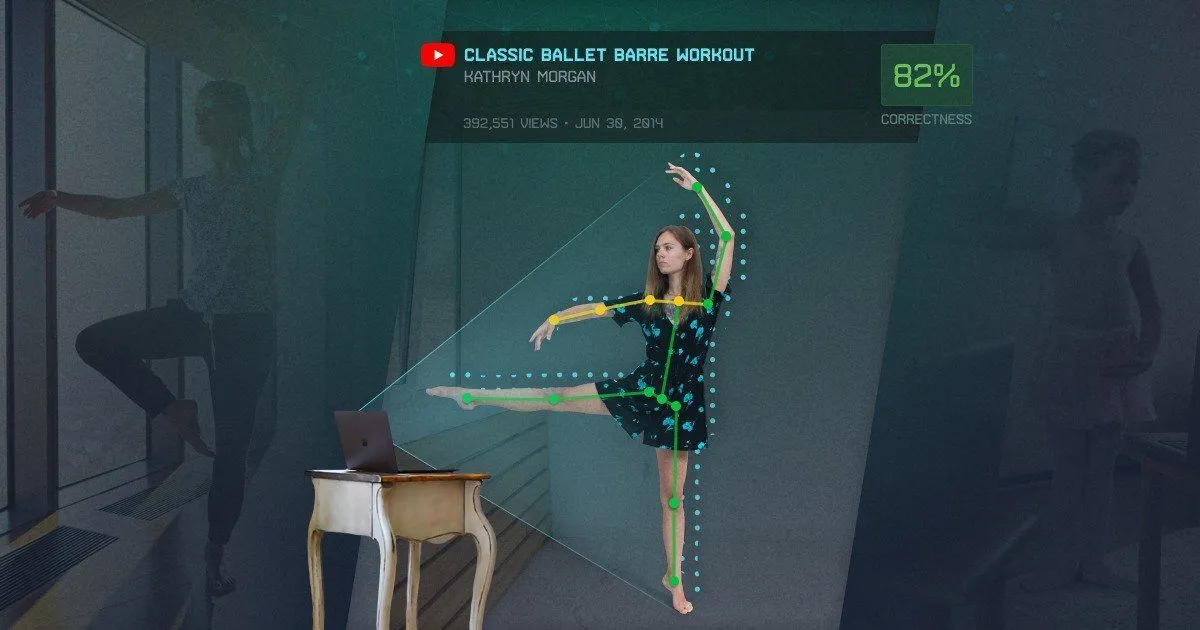

Using our AI-powered system, the LiDAR sensor scans the components in a rotating vise. The system processes the scans and compares each unique detail with its perfect model. Any deviations are quickly identified and corrected. So, every component surely meets top-notch quality standards no matter its design or specifications.

Impact

-

The introduction of this AI-powered system completely revolutionized the production operations for our client. By automating tasks in manufacturing settings they gained a significant boost in productivity and flexibility.

-

Additionally, the manufactory cut down on both time and expenses related to prototyping and testing by simulating these processes using NVIDIA Omniverse Isaac Sim. Furthermore, the advanced processing of point clouds ensures that each component meets quality standards thereby improving the precision and reliability of the company’s products.

A robot picks up the factory-made detail

An example of the object’s deformation

Detection of the deviated parts

Need Computer Vision algorithm for your idea?

Talk to Yuliya. She will make sure that all is covered. Don't waste time on googling - get all answers from relevant expert in under one hour.