Cyberhawk: The Future of Drone Inspections with BVLOS

Chris Fleming shares Cyberhawk's journey from rope access to AI-driven UAV solutions.

Founded in 2008, Cyberhawk was the first company in the world to use unmanned vehicles to inspect industrial assets. Cyberhawk's world-class pilots and inspection engineers have completed over 200,000 UAV inspection missions, with 300+ customers, in over 40 countries.

Today, the Cyberhawk team continues to lead close visual inspections of critical assets including electrical grids, power generation sites, oil and gas structures and capital-intensive industrial construction projects — while always putting safety at the forefront of their operational excellence. Company combines engineering expertise, world-class drone operations, and purpose-built software to deliver end-to-end solutions that support infrastructure asset management program.

With offices in Edinburgh, Denver and Doha, Cyberhawk has seen a period of rapid expansion on the back of increased demand, particularly in North America, and through £3.3m in funding secured from investors such as Magnesium Capital and Scottish Equity Partners among others.

Yuliya sits down with Chris Fleming, Cyberhawk's CEO, for a conversation about company's journey, its capabilities and the future of UAVs.

Yuliya Sychikova [YS]: As a pioneer in the drone-based inspection industry, what inspired you to found Cyberhawk, and how has the company evolved since its inception in 2008?

Chris Fleming [CF]: Our founders were all rope access trained inspectors who carried out difficult and dangerous jobs in the harsh environment of the North Sea in Scotland. The idea was simple. We wondered if we could use a drone to inspect without having to send someone underneath an oil and gas platform?

We have always been an inspection company first and foremost, but the volume of data drones collect compared to traditional inspection techniques meant we needed to invest in our own software. It was necessary to manage drone data and provide our customers information in a manner they can make decisions. Demand for our software solution is growing faster than in other parts of the business as many companies look for a tool to manage their drone data and enable faster, more efficient decisions.

[YS]: Could you share some insights into the significance of using UAVs for inspecting industrial assets, and how this approach has transformed traditional inspection methods?

[CF]: Any time you remove a human from a hazardous place and allow them to carry out the inspection by reviewing data or imagery from the comfort of an office, the likelihood of finding a defect increases.

Humans will still be required to conduct further inspections and repairs, but the risk is reduced. They only need to access these areas when there is a genuine requirement to repair them and when they go on site they know exactly what they need to fix in advance. Drones can often perform inspections in less time and at a lower cost. We have also proved that drones can complete the task without the need to shut down assets which saves money as well.

Drones can often perform inspections in less time and at a lower cost. We have also proved that drones can complete the task without the need to shut down assets which saves money as well.

[YS]: With your experience in sectors like power generation, oil & gas, mining, and utilities, how do you see the role of drones and AI-driven software in enhancing asset management programs across these industries?

[CF]: The high-quality imagery available from UAVs allows evidence-based decision-making with data available to back up and justify expensive repair and maintenance decisions. It also allows inspections and surveys to be completed more frequently as they can be completed faster, at lower cost and higher safety. However, drones collect large volumes of data compared to traditional inspection and survey techniques, so AI is required to efficiently identify components and areas of interest.

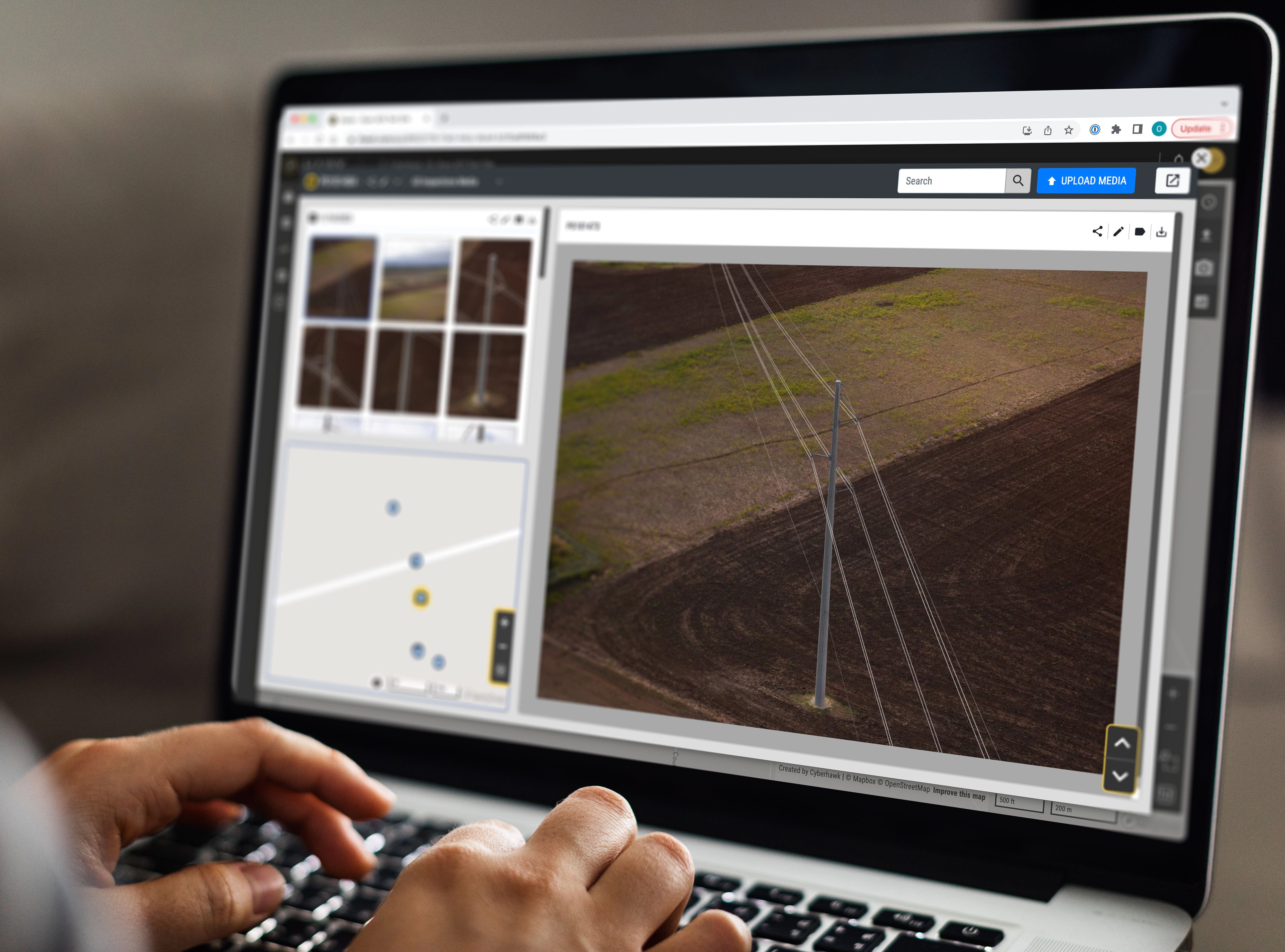

Inspection in progress by Cyberhawk team

[YS]: How does Cyberhawk leverage AI and machine learning within its software solutions, such as iHawk?

[CF]: We have an internal AI team who has developed models to identify components and defects. We are now working on grading defects so we can tell how good or bad condition they are in, and the effort required to repair them. Recently, we have also developed an in-house face-blurring AI module. Here, any face in our imagery is blurred before being used, supporting GDPR.

[YS]: With the adoption of Intelligent Energy's IE-SOAR™ fuel cells, how does Cyberhawk ensure better quality data and increased operational efficiency for its customers?

[CF]: We are keen to fly BVLOS as the regulation allows and we recently secured our BVLOS waiver in the US. To maximize this, we need our drones to fly longer, and hydrogen fuel cells is one way of doing this. As we can fly BVLOS with longer flight times, we can start to replace some manned aircraft scopes, with this advantage and increased safety, reduced cost and less environmental impact. We are also focusing on automation to ensure that quality is maintained during these longer flight times.

iHawk, cloud-based visualization software platform by Cyberhawk

[YS]: As drone technology advances, what emerging applications do you envision for drones in the sectors you serve?

[CF]: As BVLOS, automation and longer flight times become possible, drones will start to replace more manned aviation scopes. Additionally, up to this point all inspections and surveys have been remote visual and thermal, but now we are moving to conduct inspections and surveys with UT sensors. This will open a new market and again, remove people from working in dangerous environments such as heights or in confined areas.

As BVLOS, automation and longer flight times become possible, drones will start to replace more manned aviation scopes.

[YS]: Can you provide examples of how drones have been instrumental in supporting emergency response missions, and how Cyberhawk's expertise contributes to this aspect of drone utilization?

[CF]: We have a contract for 24/7 emergency response in the Middle East and we have teams on standby so that drones are on hand to respond to any kind of accident at any time. Drones can then provide additional information on any situation and be delivered in real time to support any emergency response.

We also have relationships with many critical asset owners who use our drone expertise to support emergency response situations. This can involve high-level flyovers to provide situational awareness to detailed inspections of damaged assets to understand their condition and often, short-term safety.

Combining automation with BVLOS permissions and increased drone flight times will allow scopes to be completed more cost-effectively and support scopes traditionally completed by manned aircraft.

[YS]: When it comes to drone autonomy, where are we at the moment, and where are we headed? How does Cyberhawk see its role?

[CF]: We are currently in the relatively early stages, but we anticipate it will revolutionize the efficiency of drone inspections and surveys. Combining automation with BVLOS permissions and increased drone flight times will allow scopes to be completed more cost-effectively and support scopes traditionally performed by manned aircraft.